No products in the cart.

Making

MADE

IN

INDIA

From the thinly populated Hanle, Korzok andChushul to the quaint town of Ladakh, our rawcashmere discovers its true beauty on thelooms of Srinagar.

Unique, elegant, stylish and luxurious best describes our cashmere.

The craftsmanship, handiwork and dedication of many makes a near perfect piece.

Each skill set is mastered by a multitude of people who over a period of time and many generations have refined it.

There are 7 to 12 stages involved in the making of cashmere. Most of the steps are manually implemented, making it a long and arduous process.

1.

The Cashmere Goat

The Capra hircus begins its descend towards greener pastures of Rupshu, Korzok and Hanle in the month of February

2.

Fibre Harvesting

This begins in june and is over by the first week of August. The pashm, raw cashmere is removed by combing and shearing. Done with indigenous tools, the Changpa tribe do it in stages so that the goat keeps warm

3.

De-hairing

Raw hair is sorted out manually to remove admixture of outer coarse hair. A painstaking process, it takes eight hours to de-hair 50gms of pashm.

4.

Glueing

The Capra hircus begins its descend towards greener pastures of Rupshu, Korzok The fibres are put in a large basin and sprinkled with pounded rice. This is left for two nights to strengthen the strands.

5.

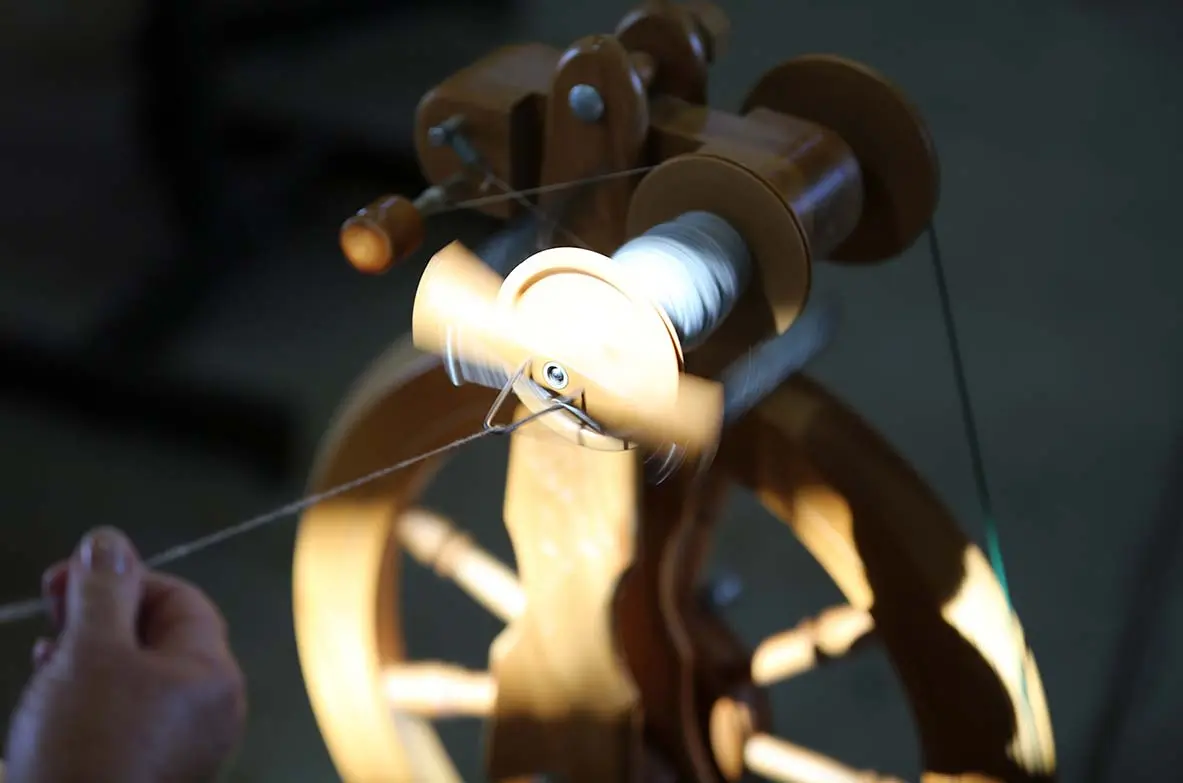

Spinning

This is done manually on a spinning wheel locally called charkha. The charkha converts the fluff into yarn.

6.

Plying

The yarns are then made into hanks, which are opened on large wooden stands. It is then mounted on wooden spindles termed as prech.

7.

Weaving

The yarn is separated for the use of wrap and weft and isweighed before weaving. The warp maker twists the yarn to the desired thickness and steeps it in rice water, in a copper vessel for two days. The yarn is then dried & stretched. Twelve hundred stretched threads are fixed in the heddles of the loom to create a running cashmere fabric of four to six scarves. This takes close to two weeks, after which the process of weaving begins.

8.

Finishing

The hand woven drape is tweezed, clipped and brushed to rid of flaws and loose fibres on the surface.

OUR JOURNEY

Our Cashmere covers a total distance of 1492 kilometers(927 miles) , from Hanle to New Delhi.

The raw cashmere, pashm, begins its journey in jute sacks and reaches Ladakh covering a distance of 255 kms.

Our pashm is then transported to Srinagar covering a distance of 422 kms. The grubby and greasy mass is transformed to a fabric of gossamer fineness.

Absolute Pashminas finished products begin their journey to New Delhi covering a distance of 815 kms.